ENERGIRON references

Hydra, Rina

Capacity: Pilot Plant

Products: Hot/Cold DRI -HBI

Start up year: In progress

100% Hydrogen Feed

EDRP, Nippon Steel

Capacity: Pilot Plant

Products: Hot/Cold DRI -HBI

Start up year: In progress

100% Hydrogen Feed

MD1 Plant, LKAB

Capacity: 1.35 MTPY

Products: Cold DRI-HBI

Start up year: In progress

100% Hydrogen Feed

Vulcan Green Steel, Jindal Shadeed Iron and Steel

Capacity: 2.5 MTPY

Products: Hot DRI-HBI

Start up year: In progress

5M, Ternium

Capacity: 2.1 MTPY

Products: Hot/Cold DRI

Start up year: In progress

100% Hydrogen Feed

HERACLESS, TATA Steel Netherlands

Capacity: 2.5 MTPY

Products: Hot/Cold DRI

Start up year: In progress

SALCOS, Salzgitter Flachstahl

Capacity: 2.1 MTPY

Products: HDRI/CDRI

Start up year: In progress

Baosteel Zhanjiang, Baowu Group

Capacity: 1.0 MTPY

Products: Cold DRI

Start up year: 2023

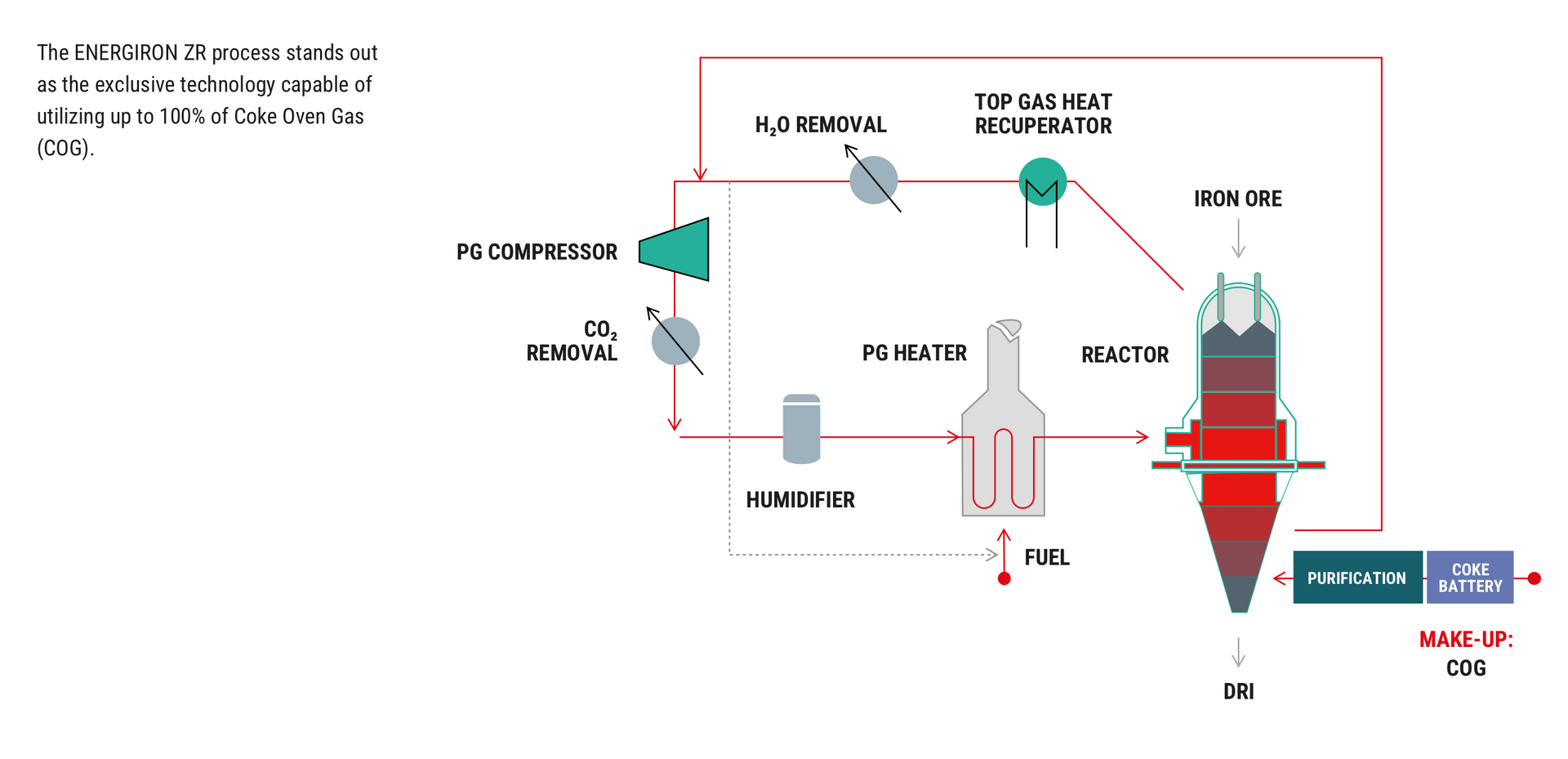

Coke Oven Gas, Natural Gas, and Hydrogen Feed

Hebei Iron & Steel Group (HBIS)

Capacity: 0.55 MTPY

Products: Cold DRI

Start up year: 2023

Coke Oven Gas Feed

μDRAL, Salzgitter Flachstahl

Capacity: Pilot Plant

Products: Cold DRI-HBI

Start up year: 2022

100% Hydrogen Feed

HYBRIT Development AB

Capacity: Pilot Plant

Products: Cold DRI-HBI

Start up year: 2021

100% Hydrogen Feed

Empresa Siderurgica Mutun (ESM)

Capacity: Pilot Plant

Products: Cold DRI

Start up year: In progress

EZZ Rolling Mills

Capacity: 1.9 MTPY

Products: Cold DRI

Start up year: 2015

Turnkey project

Nucor Steel

Capacity: 2.5 MTPY

Products: Cold DRI

Start up year: 2013

Suez Steel

Capacity: 2.0 MTPY

Products: Hot/Cold DRI

Start up year: 2011

GHC II Emirates Steel Arkan

Capacity: 2.0 MTPY

Products: Hot/Cold DRI

Start up year: 2011

Turnkey project

GHC I Emirates Steel Arkan

Capacity: 2.0 MTPY

Products: Hot/Cold DRI

Start up year: 2009

Turnkey project

-

plants in operation

-

ongoing projects

| Name | Location | Status |

|---|---|---|

| Hebei Iron & Steel Group (HBIS) | Hebei, China | Plants in operation |

| Baosteel Zhanjiang, Baowu Group | Guangdong, China | Plants in operation |

| μDRAL, Salzgitter Flachstahl | Salzgitter, Germany | Plants in operation |

| HYBRIT Development AB | Luleå, Sweden | Plants in operation |

| EZZ Rolling Mills | Cairo, Egypt | Plants in operation |

| Nucor Steel | Lousiana, USA | Plants in operation |

| GHC II Emirates Steel Arkan | Abu Dhabi, UAE | Plants in operation |

| Suez Steel | Cairo, Egypt | Plants in operation |

| GHC I Emirates Steel Arkan | Abu Dhabi, UAE | Plants in operation |

| Empresa Siderurgica Mutun (ESM) | Puerto Suarez, Bolivia | On going projects |

| SALCOS, Salzgitter Flachstahl | Salzgitter, Germany | On going projects |

| HERACLESS, TATA Steel Netherlands | Ijmuiden, Netherlands | On going projects |

| 5M, Ternium | Pesqueria, Mexico | On going projects |

| Vulcan Green Steel, Jindal Shadeed Iron and Steel | Duqm, Oman | On going projects |

| MD1 Plant, LKAB | Gällivare, Sweden | On going projects |

| EDRP, Nippon Steel | Kamisu, Japan | On going projects |

| Hydra, Rina | Rome, Italy | On going projects |

ONE PLANT,

ENDLESS POSSIBILITIES

Powered by any energy,

suitable for any ore

DRI

ENERGIRON produces high quality Direct Reduced Iron (DRI) with a high metallization rate and high carbon content, making it ideal for superior steelmaking.

High & Consistent Metallization

DRI is produced at high metallization. Thanks to the higher operating pressure, DRI quality is stable and consistent for improved steelmaking performance.

Adjustable Carbon Content

Carbon content in DRI can be set as required, providing additional chemical energy to the steelmaking process.

The range of carbon content is wide enough to satisfy all steelmaking needs.

For any form of DRI (CDRI, HDRI, HBI) ENERGIRON can provide additional chemical energy in the form of carbon.

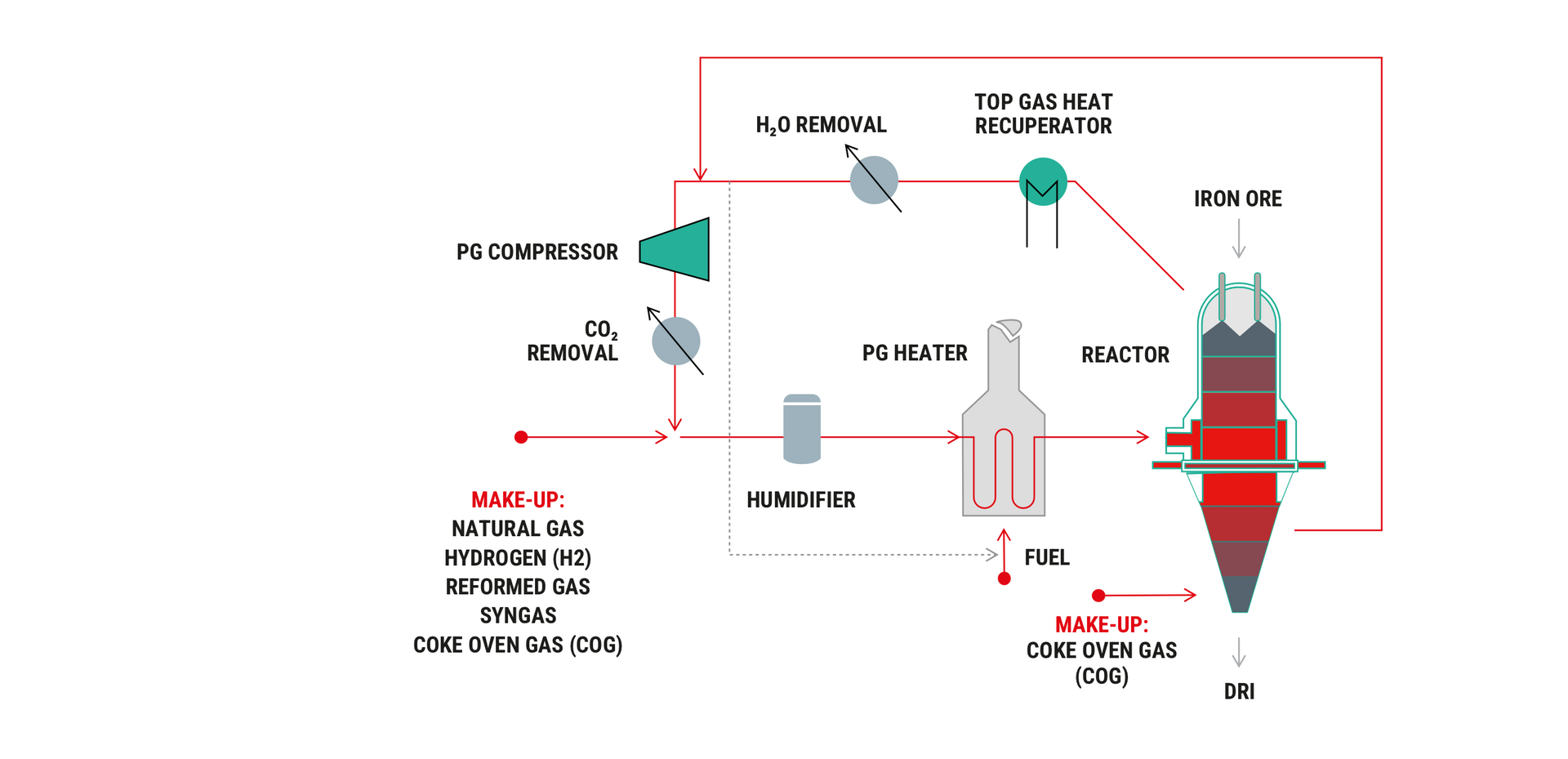

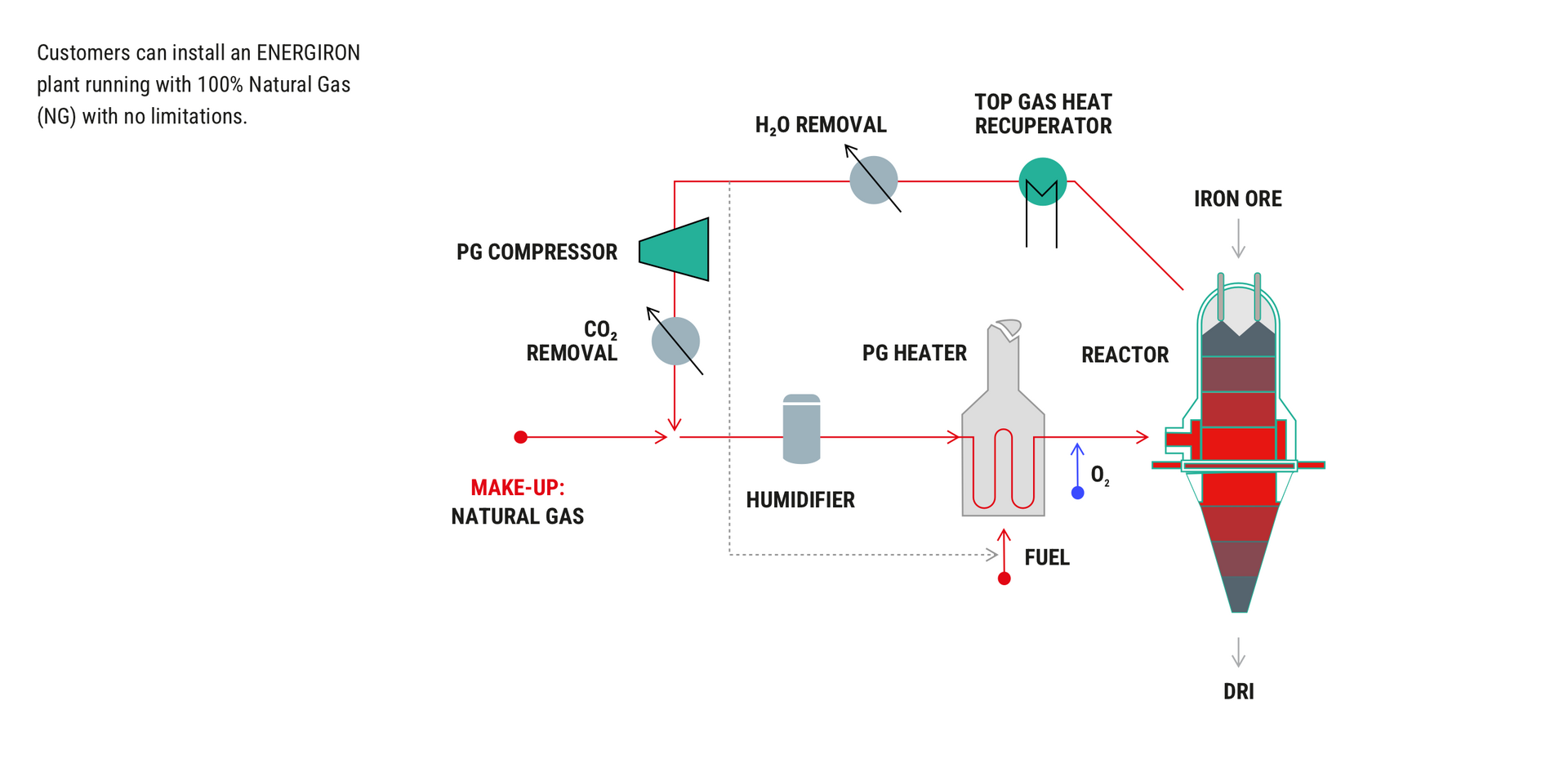

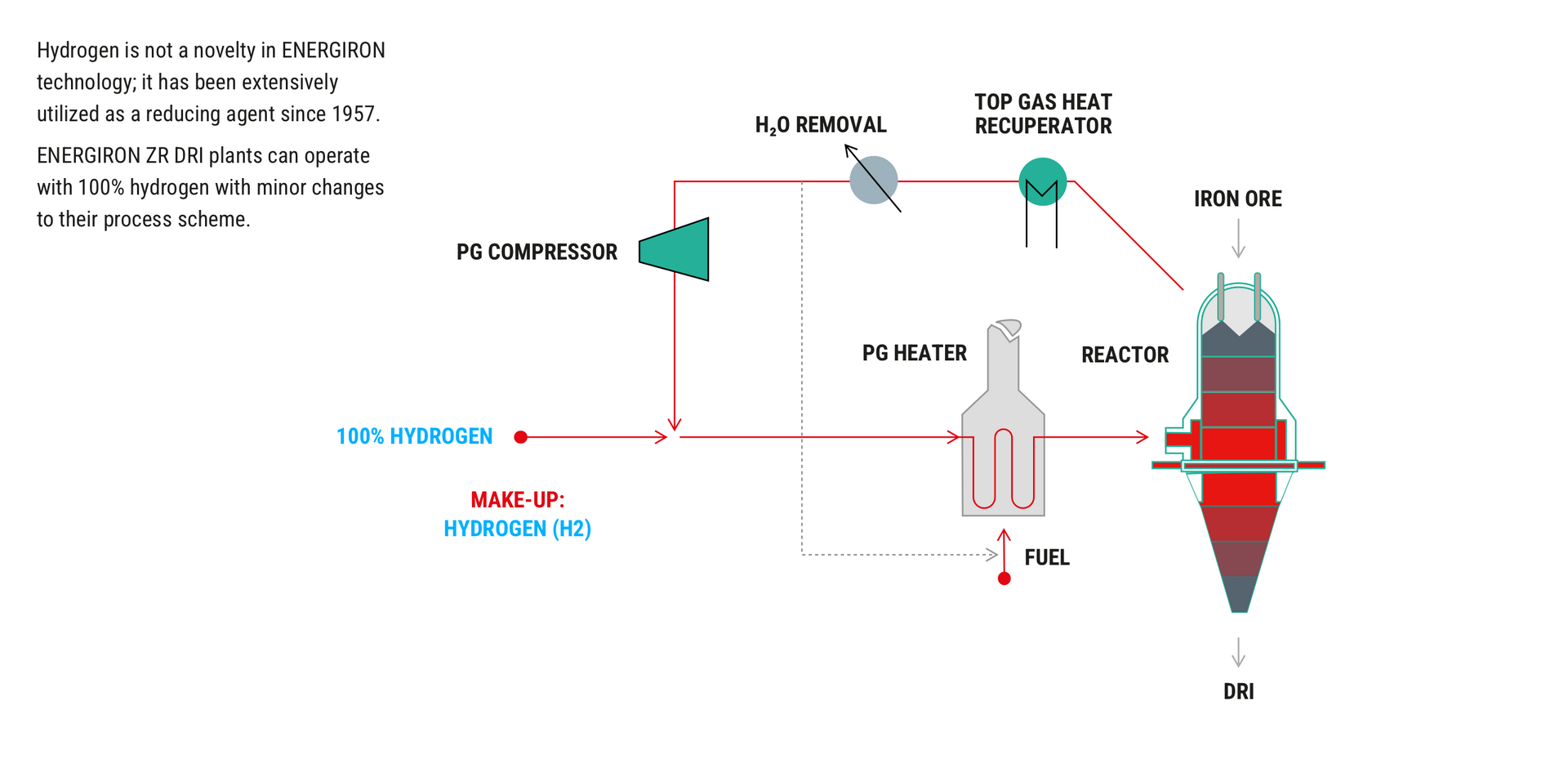

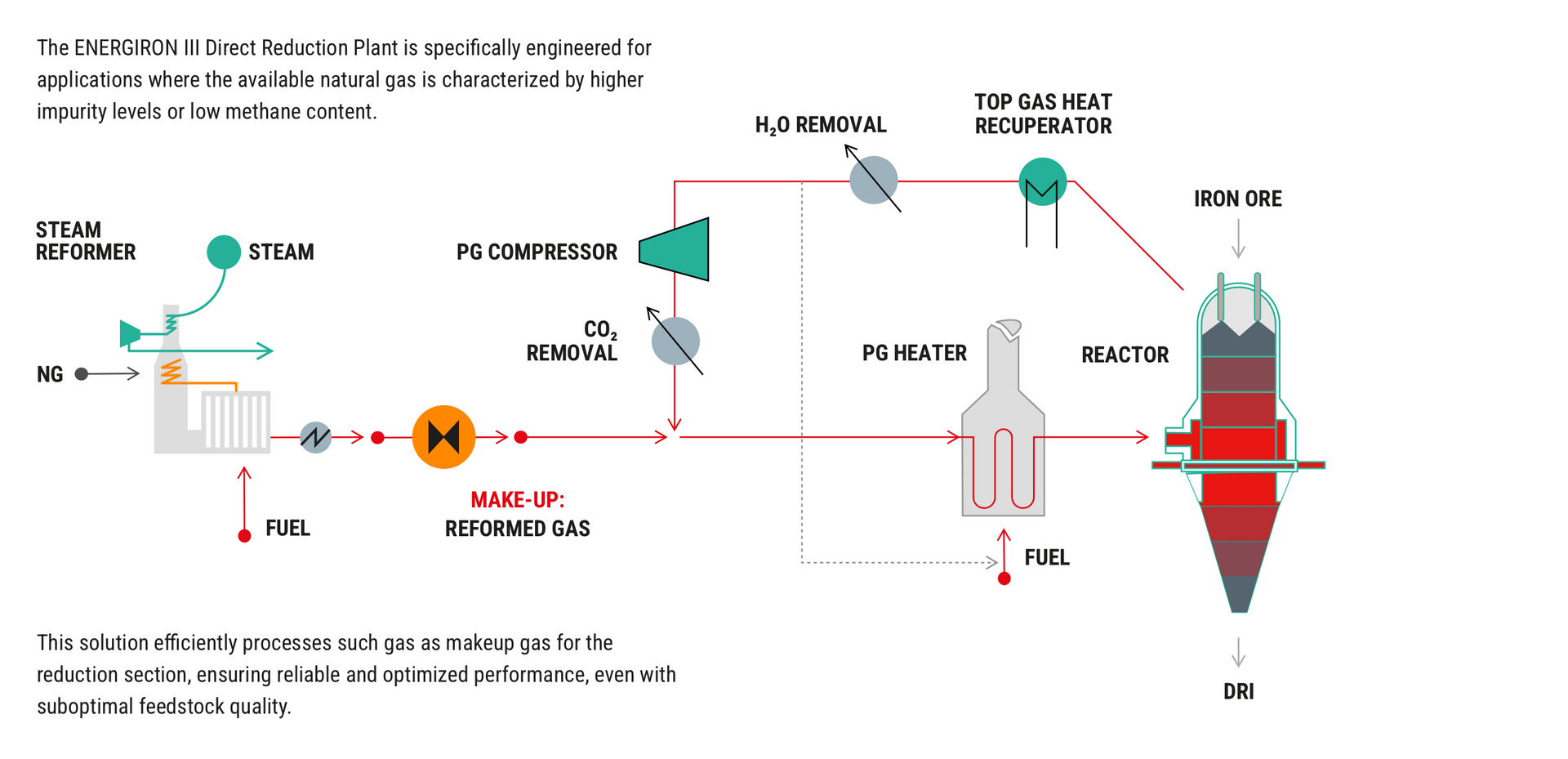

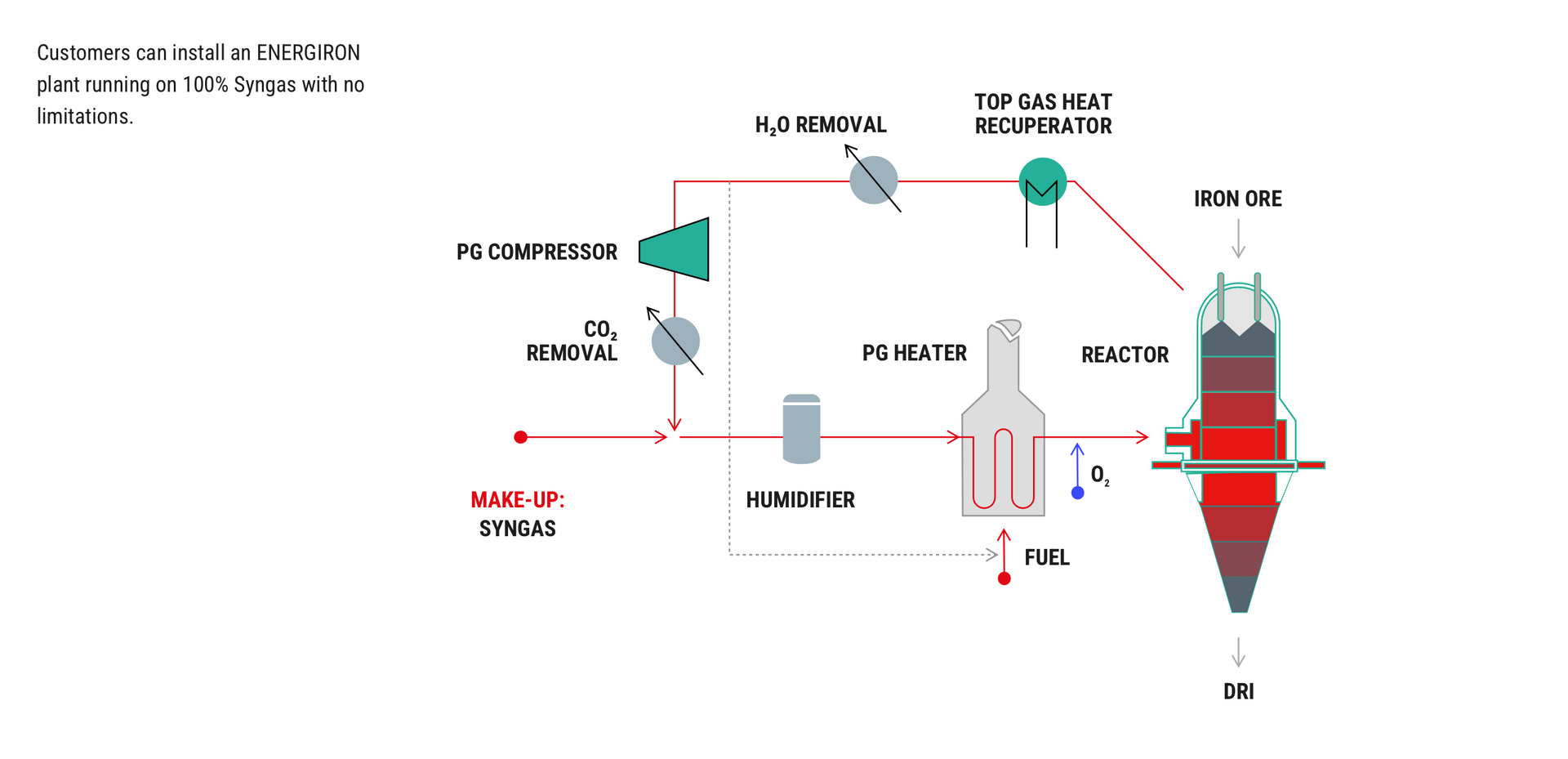

A technology for flexible solutions

ENERGIRON technology is extremely flexible, accommodating various hydrogen-containing reducing gases (natural gas, syngas, coke over gas, hydrogen) and iron ore qualities. It operates under diverse conditions, utilizing locally available resources at competitive prices. This versatility ensures efficient, cost-effective, and environmentally friendly production, making ENERGIRON a robust solution for the evolving needs of the steel industry.

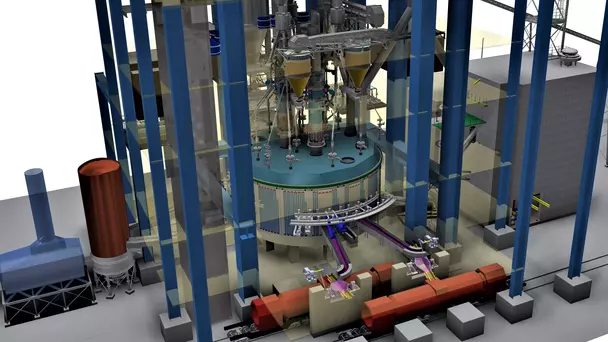

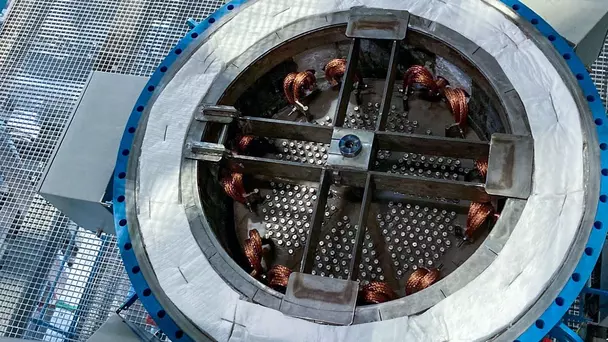

Integrated features

ENERGIRON technology encompasses several advanced integrated features designed to optimize the direct reduced iron production processes.

Services

At the heart of our ENERGIRON technology is a commitment to exceptional technical support and services. We prioritize our customers’ operational efficiency, safety, and reliability, ensuring that their Direct Reduction Plant runs smoothly. Our proactive approach helps prevent costly downtime and unexpected breakdowns, allowing our customer to focus on what matters most. We value working collaboratively to address every customer need, delivering innovative solutions that enhance performance and productivity.